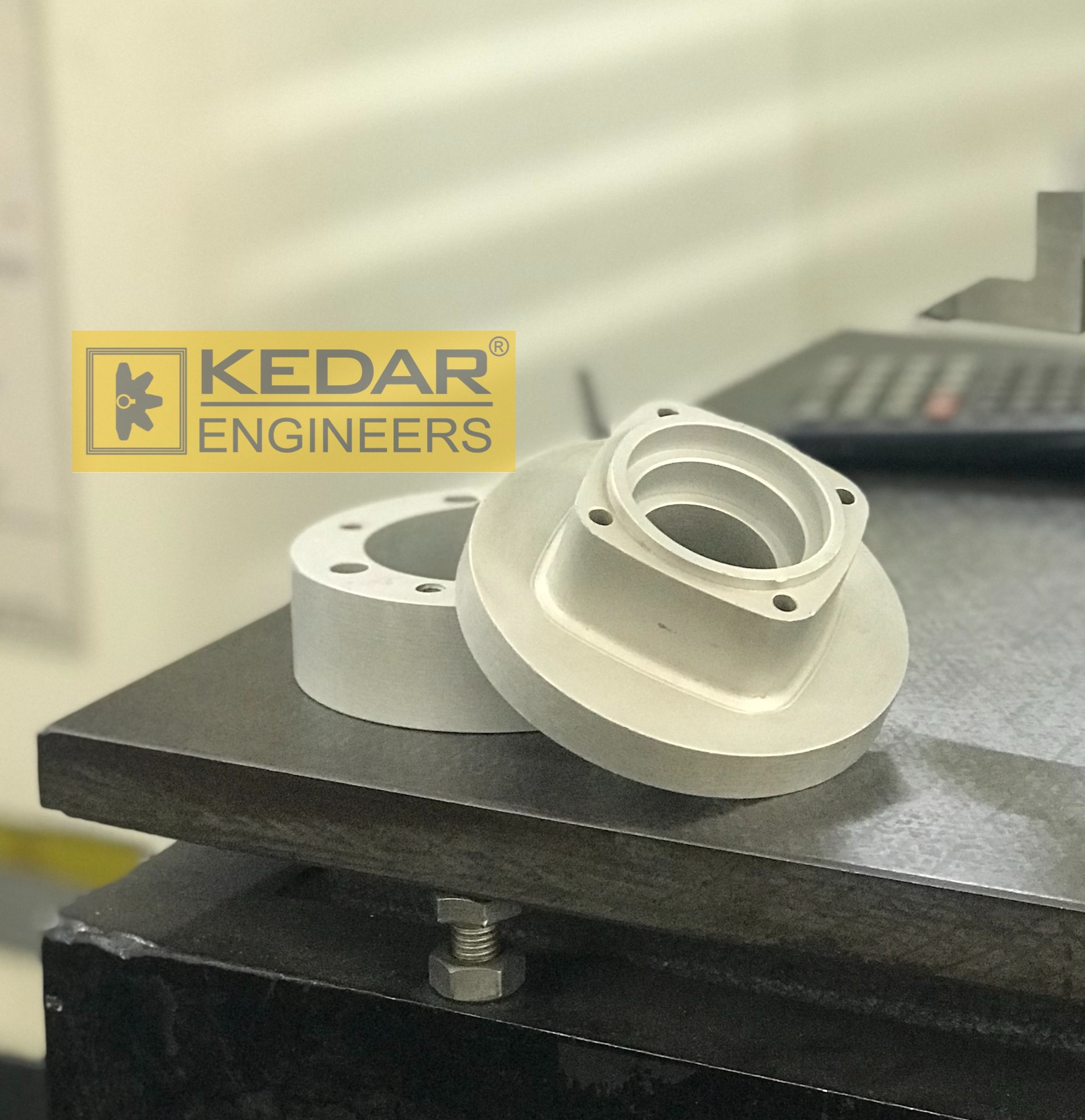

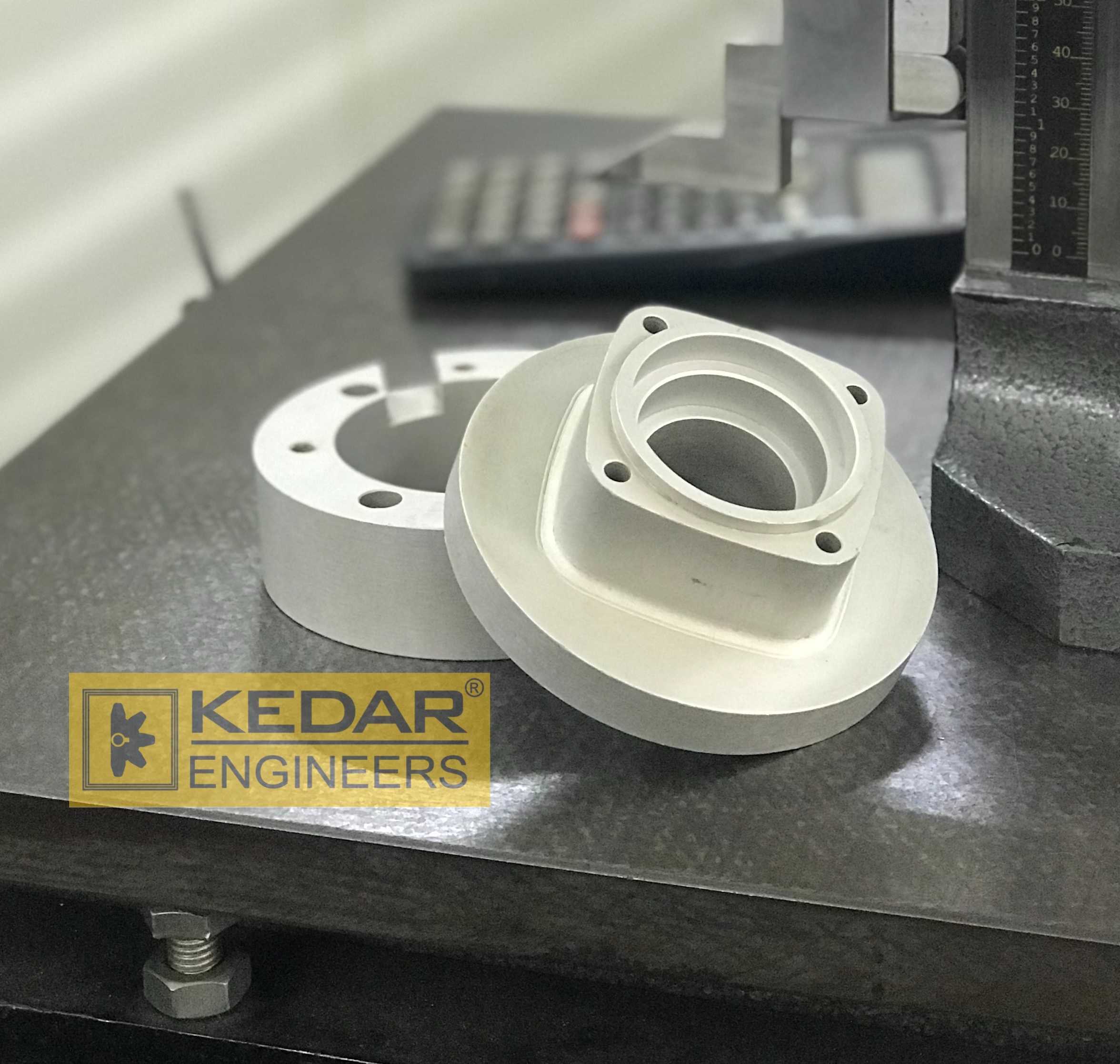

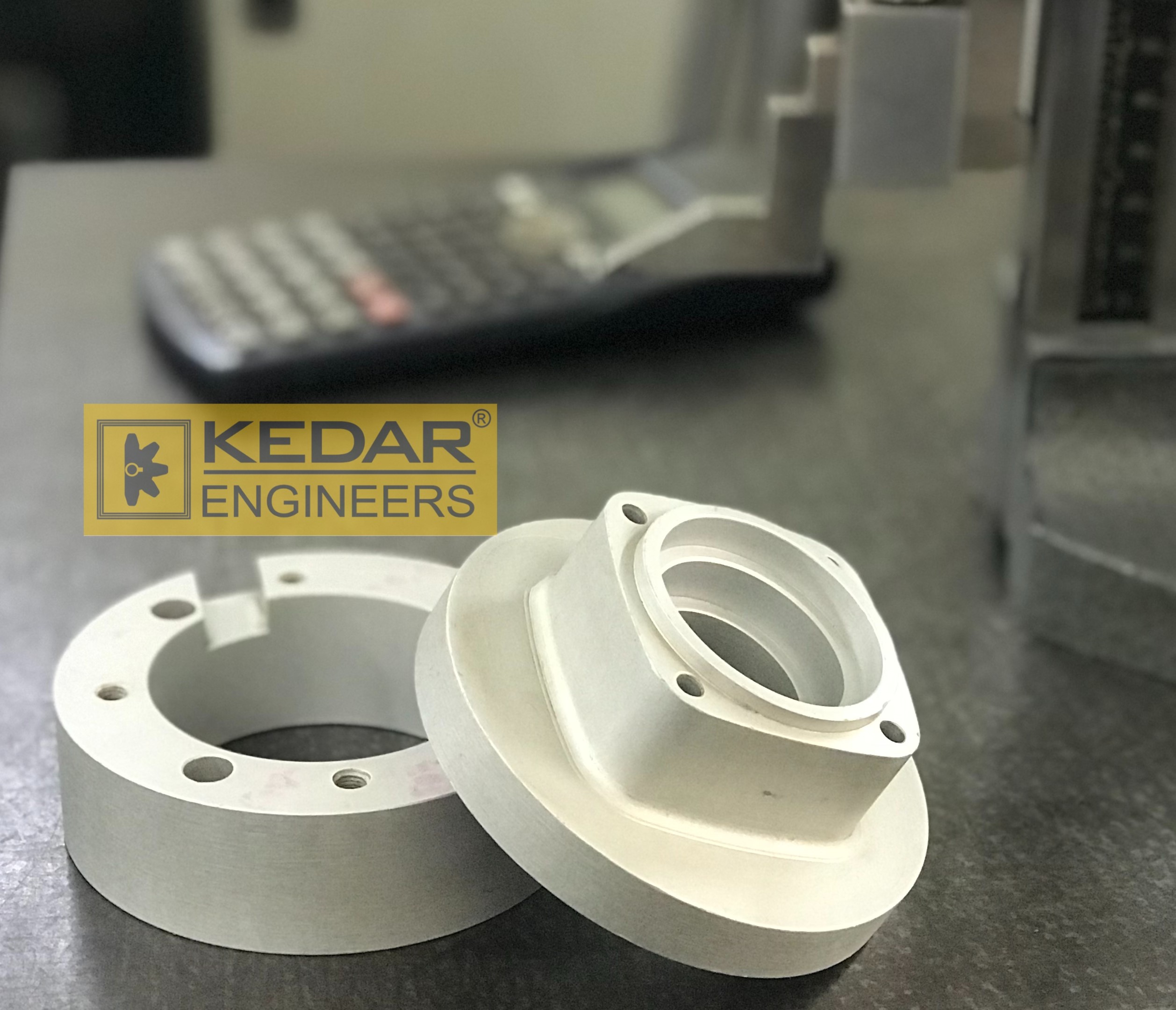

MACHINED COMPONENTS

As a superior in precision component manufacturing, Kedar Engineers has the right tools, resources, and experienced research and development team to help development of your precision components. From simple design and development of components that require complex work for multi-functional use and every little thing in-between, we have dealing in it all.

Our Hi-Tech and advance machining technology concede us to perform milling, turning, Drilling, Taping, boring, cross-drilling and other machining techniques using a undivided machine. All-in-one machining operations like this concede to defeat costly secondary operations, saving you time and money while ensuring your part is produced to your exact specifications.

MATERIALS WE MACHINED

Stainless Steel: SS316, SS316L, SS304, SS304L, SS303, SS310, SS321, SS317, AISI 317L, SS410, MS 211-9, SS416, SS416S41, 1CR13 SST, SS446. Monel, Monel K500, Inconel, Hastelloy.

Brass: C36000, C37000, HPB59-1, ASTM B16, B248, MS202-1, ASTM B591, HBP62-3.

Mild Steel: M.S, 12L14, C1018, EN8M, EN8AM, EN19, G3000, ASTM A48, SA 29 Gr.4340:2017, BS970, C45, EN8, En9, En19, En24 all En grades.

Casting: CD4MCU, BRASS, CF8.

Aluminum: 6262-T9, 2024-T351, 2017-T451,2011-T3,6061-T6, ALUMINIUM BRONZE, IS 7814 Gr I, He30 Lm6.

Copper, Delrin, Nylon, All types of aluminum, all types of ferrous and non- ferrous materials.